Marking & Coding Equipment

Rite-Way offers a complete lineup of marking and coding equipment by industry leader Markem-Imaje which are designed for various markets from food and beverage to cosmetics, electronics, agriculture and more.

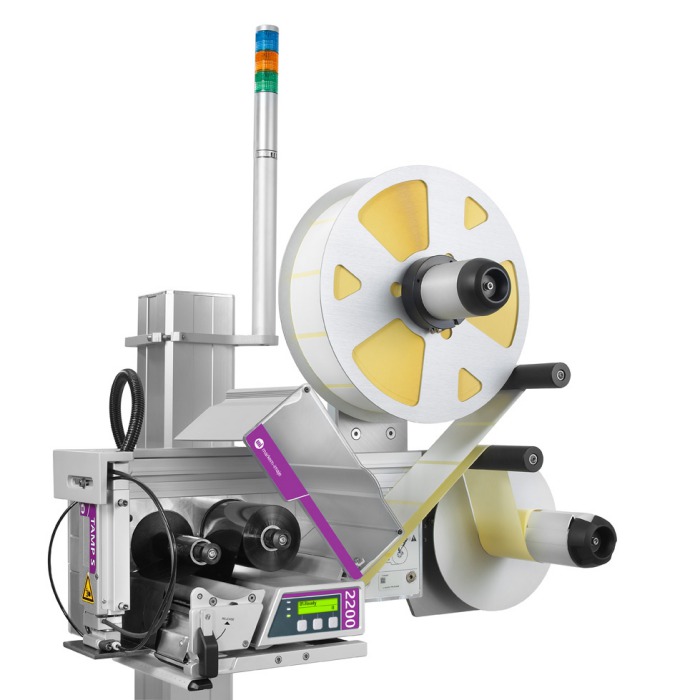

Our Marking & Coding Equipment includes full-featured printers designed for high-demand manufacturing environments. These versatile printers deliver precise, high-contrast markings and codes on a variety of substrates, from standard packaging materials to specialized surfaces.

- High-Performance Marking: Capable of printing high-contrast codes, barcodes, and logos with clarity.

- Multi-Substrate Compatibility: Designed to print on cardboard, plastics, metals, glass, and other materials.

- Durable Construction: Built for rugged, demanding environments with reliable performance.

- Flexible Applications: Suitable for both general-purpose and specialized applications, including high-speed production lines.

- Compliance Ready: Ensures traceability and meets industry regulations for labeling and coding.