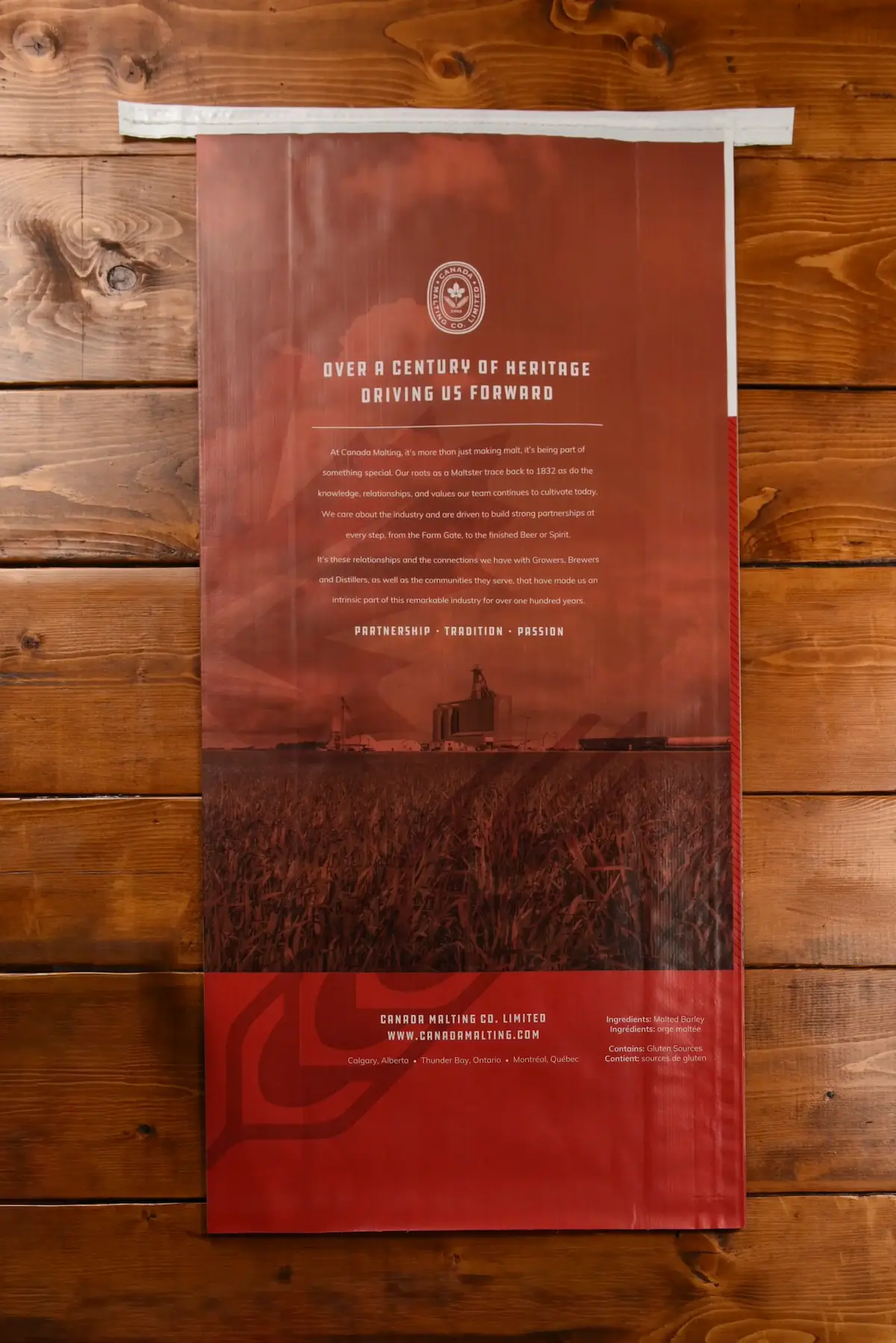

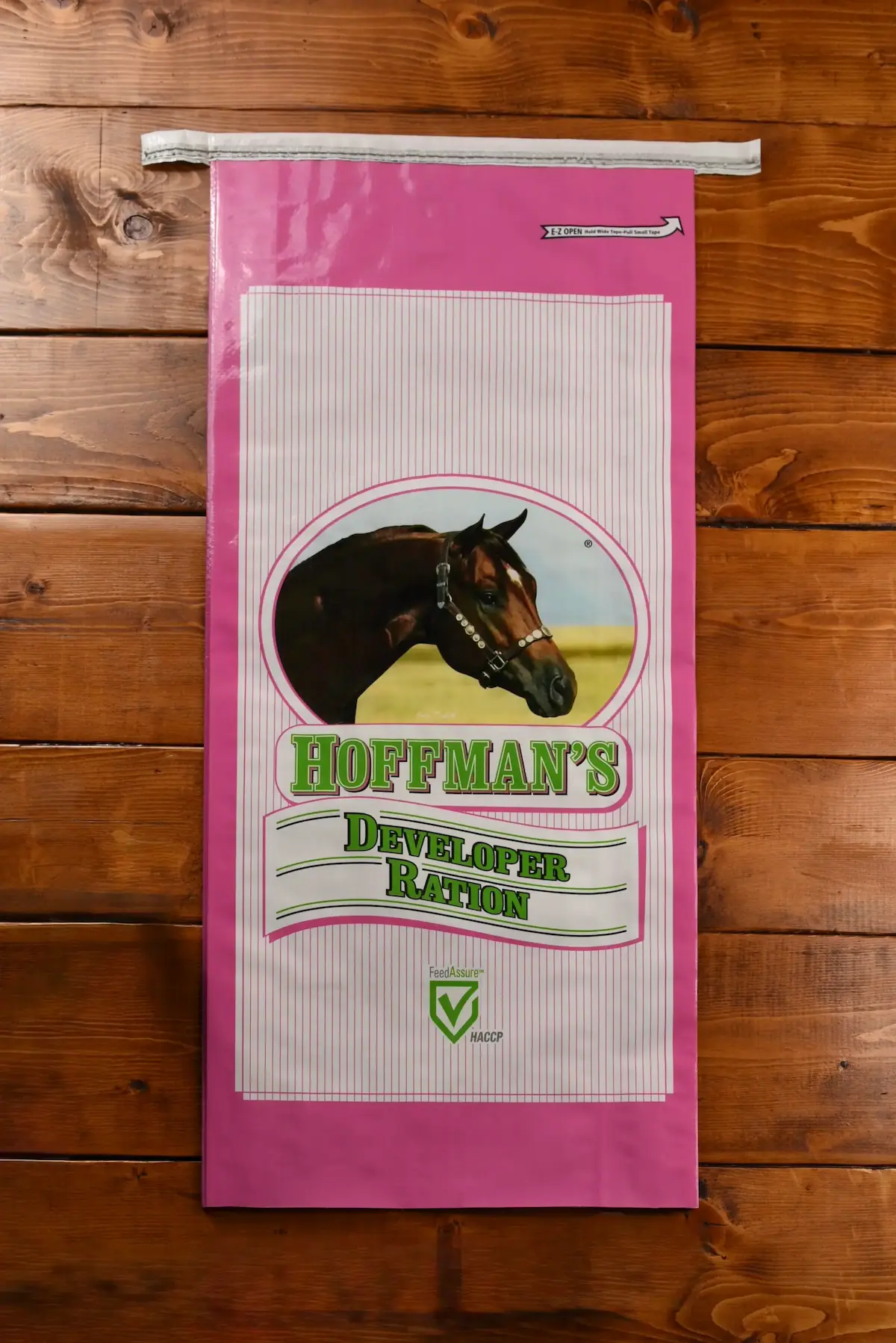

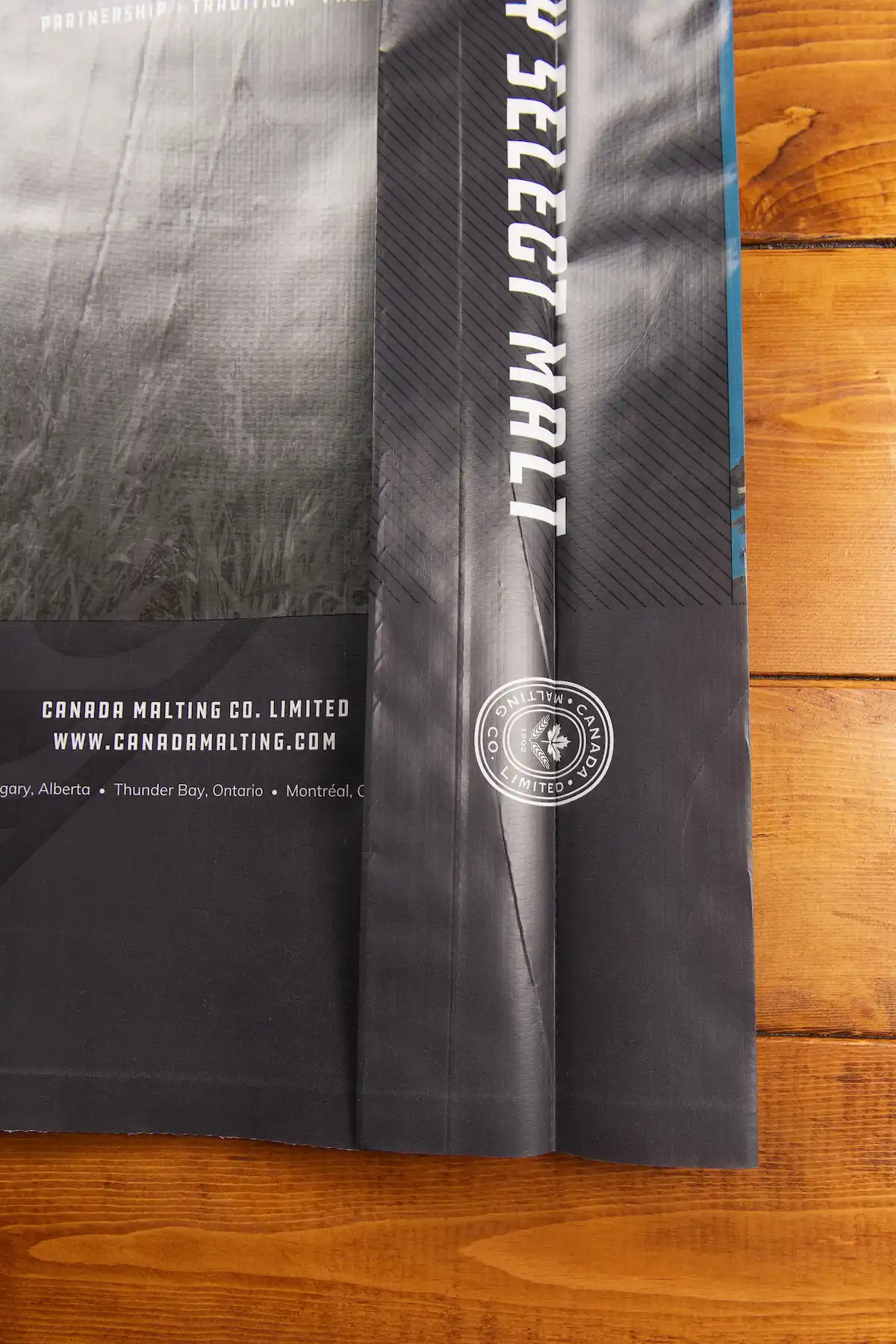

BOPP / Polywoven Laminated Bags

Durable, lightweight, and fully recyclable, BOPP/Polywoven Laminated Bags offer top-tier protection and high-quality print options for industrial packaging.

Key Features

100% recyclable

high definition graphics

water resistant

high strength/low weight

- matte or gloss finish

- high coefficient or friction film

- thermal and extrusion welded back seams

- thermal weld heat seal or sewn closures

- clean windows

- die-cut handles

- micro-perfections

- spot varnish

View Our Bag Styles & Features Guide →

Polywoven Packaging

In this video, James reviews:

- What is a polywoven bag and what are PWL bags used for?

- Are polywoven bags recyclable?

- What type of bags should I use for poultry/beef/livestock feed? What are the best bags for minerals?

- Are paper bags polywoven bags good for chemicals / food ingredients / powders / aggregates?

And more!

Learn More →

CONTACT US TO START YOUR ORDER

Related Articles

Moisture Resistant Packaging – Types and Uses

Moisture Resistant Packaging – Types and Uses What requirements do you need for packaging animal feed? What about spices, powders, or commodities? There are numerous packaging solutions that can be used for dry commodities. Above all, these packagings need to be moisture resistant. A combination...

Polywoven Packaging – Types and Uses

What are some cost-effective packaging solutions for dry food materials? Paper and polywoven laminated bags offer great advantages to our industrial and agricultural clients. Therefore, these bags offer great benefits over traditional multi-wall paper bags. These bags are used to package contents such as animal...

Monofilm and Composite Packaging – Types and Uses

Monofilm and Composite Packaging – Types and Uses What’s the best packaging to use for greasy or abrasive material? Or what if you need an airtight seal to guarantee the quality of contents? Monofilm bags are made from a single layer of plastic polyethylene film. Due...

How Your Product Packaging Can Affect Your Sales

Packaging is an essential piece of the puzzle and does more than you think. Your packaging is your product’s identity....