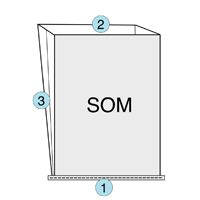

Sewn Open Mouth (SOM) Bags

SOM bags can be a multi-wall paper construction or a paper/BOPP laminated construction with a PP woven inner scrim. Features of SOM bags include:

- Sewn factory end with Easy-open function.

- Flush cut end for sewn closure by user.

- Typically SOM bags are gusseted which can be offset for easy bag placement during filling. Flat tube SOMF bags are also available.

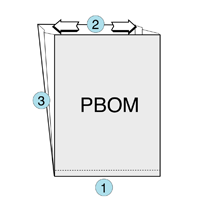

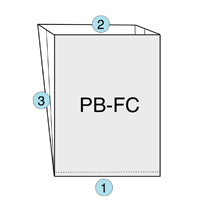

Pinch Bottom Open Mouth (PBOM) Bags

PBOM bags can be a multi-wall paper construction or a BOPP/polywoven laminated construction. Features of PBOM bags include:

- Factory end is folded over and closed with hotmelt adhesive.

- Open end can be either flush cut (FC) for sewing or stepped such that it can be folded over and hotmelt sealed with the appropriate equipment by the user.

- PBOM bags are typically gusseted.

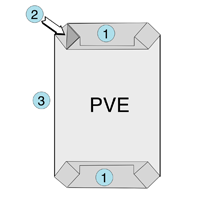

Valve Bags

Valve bags can be provided with a range of styles and options, but they all feature a valve on one end for filling the bag with a valve packer. Typically, a PVSE (pasted valve stepped end) bag is used in Canada which uses a multi-wall paper construction. Valve bags can also be made from a coated or laminated woven polypropylene fabric or a mono (PE) plastic film which feature welded seams to create the bag’s shape. Various types of valves are available including polylock or sonic seals as well as the more typical crepe paper valves which may include a tuck-in sleeve (TIS). Features of valve bags include:

- Satchel style ends.

- Valve on one end for filling with may include a tuck in sleeve (TIS).

- No gusset.

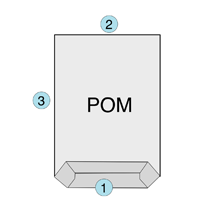

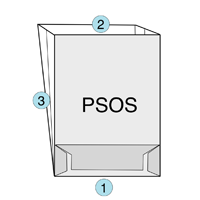

Satchel and Block Bottom, Open Mouth (PSOS and POM) Bags

These bag styles feature an open mouth for sewing closed by the user and a flat bottom which helps them to stand upright. Two types of factory formed ends are available: block and satchel style. Features of satchel and block bottom open mouth bags include:

- Block and satchel style bottom.

- Open top for sewing by user.

- Block bottom bags feature a side gusset where satchel bottom bags do not.

Quad Seal Bags

Quad Seal Bags are a type of plastic composite bag. Using a combination of laminated plastic films, all seals can be welded thus allowing for practically any style of bag to be manufactured. Quad seal bags are the larger style typically used with this material type. Each of the 4 corner seals along the gussets are welded in the factory along with the bottom (or top) seal. Quad seal bags have excellent strength which allows the user to increase their bag fill ratio while using narrow gussets to maximize shelf space. Traditional or Velcro style zippers can be added to these bags to allow for end-users to re-seal the bag to retain the freshness of the product inside. Some popular options include:

- Vents or perforations

- Clear windows

- Matte finish

- Pocket zippers

- Tear Notches

- Spot varnish

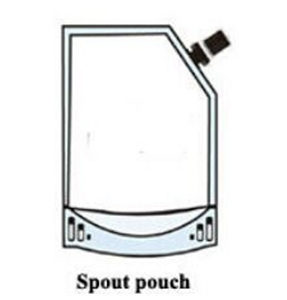

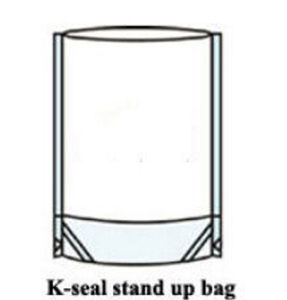

Pouches

Pouches have become a standard item in our grocery stores and confectionaries and are gaining use within the pet care and agricultural industries. Practically all pouches can incorporate (traditional or Velcro type) zippers or spouts so that end-users can re-seal package. Typically they are made from laminated plastic films (mono or composite plastics), but they can also be produced with coated kraft paper providing a more artisanal appearance and sustainable package. Pouches can be divided into two categories:

- 3-Side Seal Flat Pouch

- Stand Up Pouches

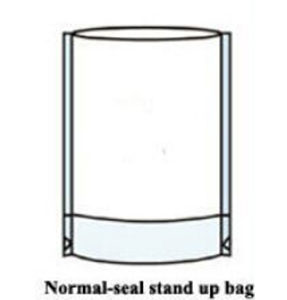

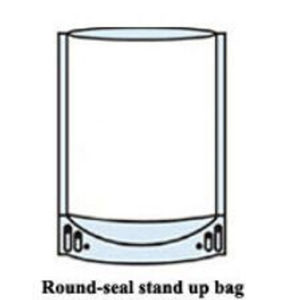

Stand Up Pouches take many variations:

- Standard

- K-Seal

- Round-seal

- Box Pouch (Gusseted Block Bottom Pouch)

- T-Shape Seal

- M-Shape Side or Edge Seal with Flat Bottom

Since there are so many options and styles of pouches available, we encourage our customers to supply samples which we can analyze and reproduce accurately.

Some key features of stand up pouches:

- Re-sealable with zippers

- Available with spouts, clear windows, easy open tear notches, and many more styles and features

- Available in materials suitable for cold or hot filling

- Size range of 250ml – 10L approximately

- Can be mono material for improved recyclability or contain various types of plastic and metalized films to suit the user’s needs.

- Poly-coated kraft paper can also be used to make pouches with a more sustainable and organic appearance.